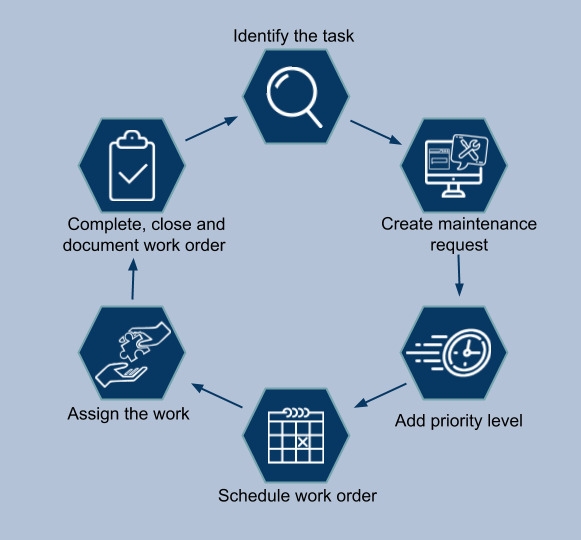

6 Steps Maintenance Work Order Workflow

every sequence of maintenance work follows a standard workflow. under this article swiss tech schreiner. give its mandatory steps:

6 steps maintenance work order workflow

step 1: define the task

when starting a job, you must first determine what the task of that job is? as for maintenance work, its tasks are divided into 2 categories: planned and unplanned.

planned maintenance includes scheduling routine maintenance sessions to prevent problems with your machinery or equipment. on the contrary, unplanned maintenance you will not know in advance, which can lead to reduced life of machinery - equipment.

step 2: set up maintenance request

once you capture the specific task, you next create a maintenance request for it. start the maintenance process. the request includes all the information about the task, along with further details such as the due date.

step 3: prioritization

if the task is forcing a "deadline," make it a priority. priority in maintenance work is also important, in order to solve problems promptly and without affecting the company.

step 4: scheduling

next, you need to schedule the work order based on when you want to complete it. if you have a set deadline in mind, then you can schedule the work order according to that deadline.

for planned maintenance, you can schedule the task beforehand and it will be initiated at the specified time.

step 5: assigning

to examine the progress of any work order through to its completion, you obviously need to assign it to someone. remember that a work order cannot begin before you assign a technician to it

when assigning, make sure that the technician chosen is available throughout the entire work order process and doesn’t have prior commitments.

if that is the case, then the technician will have to leave midway, leaving the task incomplete.

step 6: completion, closing, and documentation

this is where all the information in a work order starts transforming into action to complete the maintenance process. once all the work is done, you can close the work order request.

the closing of a work order may require a manager to sign off on it after checking that everything has been done as instructed.

lastly, you should maintain a well-documented log of the work order. this shall prove useful in the future.

swiss tech schreiner.

like many great businesses, swiss tech s. began in a garage. the year was 1990, and lothar schreiner had decided to take his decade of experience in the food processing industry and strike out on his own. with a commitment to hard work, honesty and customer service, swiss tech s. has steadily grown and is currently the largest employer of sanitary welders in west germany. in order to offer its customers in the food, beverage, and pharmaceutical industries a complete range of coverage the company supports a large staff including mobile crews, project managers, engineers, and administrative support.

add: ch 4153 reinach and hcm city vietnam

hotline: (+84) 931 - 386 - 062

phone: (+84) 931 - 386 - 062

+84931386062 ( zalo / viber / whatsapp )

email: swiss.tech.schreiner@gmail.com