Advantages and limitations of Orbital Welding technology

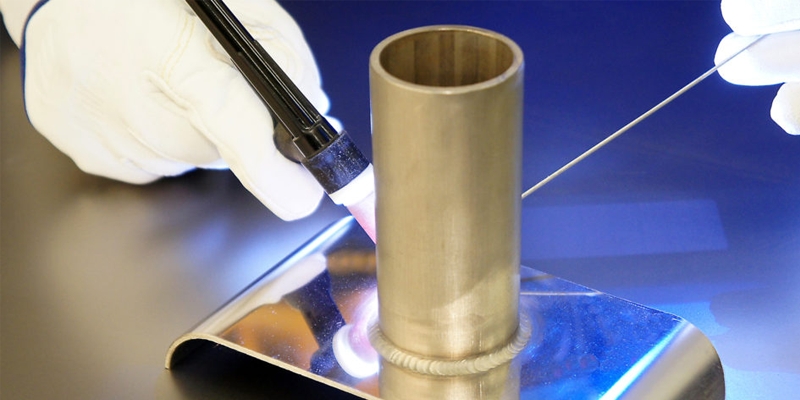

in the orbital welding process, a welding tool is rotated 360 degrees (or 180 degrees in double up welding) around a static workpiece.

when to use orbital welding

when manual welding is used in specific positions, such as down-hand and overhead, it can be challenging to establish high standards of safety and quality.

due to the user's limited access, it can be difficult for the welder to regulate the weld pool while balancing surface tension and gravity force in various torch positions, which can result in poor welds.

this problem can be resolved by automatic orbital welding technology, albeit a welder will still be needed to oversee and monitor and adjust the operation.

since the manufacture of tubing results in creating consistent outside diameters that are better for a proper fit up in the weld head.so orbital welding technology is more frequently used on tubing than on pipes.

for high purity and leak-proof integrity for liquid and gas systems required by the semiconductor and pharmaceutical industries, orbital welding has established itself as the industry standard joining technology .

due to its full automation and great repeatability, orbital welding should be employed whenever human welding would be challenging or risky, as well as whenever there is a need for several welds..

advantages of orbital welding technology

over other welding methods, orbital welding has a number of benefits, such as:

productivity rise

because orbital welding equipment is automated, it is more productive than hand tig welding because weld sequences can be reliably and quickly repeate.

consistent weld quality

he weld cycle can be repeated with a high degree of accuracy and consistency once the weld parameters have been specified and entered. the majority of orbital welding equipment enables real-time monitoring, allowing for the creation and storage of full weld protocols for future.

operator skill levels

after receiving the necessary training, knowledgeable mechanics can use orbital welding equipment. since the required skill levels are lower than those for manual welding, this leads personnel expenses ought to be cheaper as well.

environment conditions

orbital welding can be done in hazardous environments conditions , as well as in places with limited access or low vision. once the weld head is in place, the job can be finished safely away from the weld by employing video transmission to check the weld.

improved safety

by removing welders from the work area and allowing them to observe the operation from a safe distance, orbital welding can improve safety.

limitations

there are several restrictions related to orbital welding technology besides benefits.

first, not every object can be orbitally welded, and second, various welding heads are needed for welding diffirent objects.

additionally, the initial capital cost of orbital welding equipment might be 5–10 times higher than that of traditional welding.

what is orbital welding used for?

as was already mentioned, orbital welding is employed in a variety of fields and applications. this is because to the method exceptional more efficiency for otherwise complex welds in producing smooth, dependable connections .

here are a few examples of applications:

components for food, dairy, and beverage applications

because these components must meet strict hygiene and safety standards, orbital welding technology is typically utilized to create welds with a lot of smoothness and penetration for these applications.

semiconductors

in order to produce effective batch welds with flat surfaces and prevent the build-up of contaminantss, orbital welds are used for semiconductors to deliver efficient batch welds.

aerospace parts

for decades, aerospace has employed orbital welding to produce welds that can endure the stresses of flying at altitude while while remaining smooth and flawless

even with unique materials, pieces with a considerable wall thickness, small diameters, or hazardous conditions, orbital welding may produce highly repeatable, reliable welds. these elements collectively have led to the widespread adoption of orbital welding technology across numerous sectors and applications.

while the cost of the necessary equipment is somewhat costly (5–10 times as much as conventional equipment), orbital welding can provide 2-3 times higher productivity than traditional tig welding.