Information about orbital welding machines

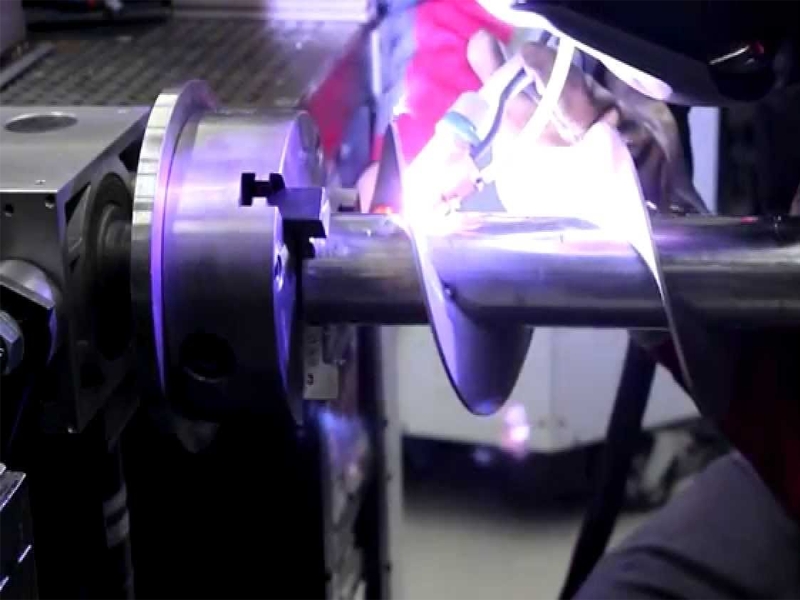

imagine the ideal weld using orbital tig welding machine in developing automation solutions!

a wide standard range of orbital welding machine is provided by orbital welding technique, including automated solutions including the latest technologies for orbital tig/gtaw tube and pipe welding

overview about orbital welding machine

worldwide, two out of every three users rely on orbital welding technique technologies and their assurance of the best possible productivity and weld quality. open and closed welding heads, as well as orbital welding power sources, are all available from orbital welding machine for a variety of applications, including:

- welding from tube to tube.

- sheet welding from tube to tube.

- every thickness of wall, from thin to thick.

- there are welding tools for all kinds of tasks.

various applications including a wide range of diameters, wall thicknesses, and workpiece geometries can readily be accommodated by modular welding heads and machine.

typically, an orbital welding system consists of the following tools:

if the application calls for it, a welding head, a wire feeding mechanism, and a programmable power supply with a remote control pendant.

to fulfill all of your needs, orbital welding technique offers entire automated installations for the tig/gtaw, cold/hot wire, and plasma processes in addition to its assortment of orbital tube and pipe welding machine. limited heat input during welding can only be ensured by automated welding, protecting the material's characteristics.

all customers' production objectives will be met thanks to orbital welding technique hardware solutions and our wide welding services.

special installations are created with the demands of the customer in mind. they often include:

- a welding power source

- a column and boom, positioner, or robot that can manipulate a workpiece or torch during welding.

with the aid of data acquisition and video components, all of these installations can be finished.

orbital welding machine: what is it?

a static workpiece is spun 360 degrees by the welding tool in an orbital welding process. a homogeneous weld around pipes and tubes, which can be challenging to achieve with manual welding procedures, is made possible by this technology, which was initially designed to address the issue of operator error in tungsten inert gas (tig) welding (also known as gas tungsten arc welding, or gtaw).

there is little requirement for a welding operator's involvement because the orbital welding method can produce high-quality repeatable welds with the aid of a computer. tube-to-tube and pipe-to-pipe joining as well as tube-to-tubesheet connecting are the two main applications for the method.

the procedure was first created by roderick rohrberg of north american aviation in the aerospace sector in 1960 to handle fuel and hydraulic fluid leakages in the x-15 rocket research plane. during the 1980s, orbital welding machines could be moved between building sites thanks to advancements in control systems, mobility, and power supplies.

what is the purpose of orbital welding machine?

where does it fit in? orbital welding has been used to produce clean-room components for the semiconductor, pharmaceutical, or ultra-high purity sectors as well as piping for a variety of industries since it can produce high purity welds.

what kind of electrode is used in tig welding machine?

tungsten electrodes that will be used for mechanical or automatic welding should be produced with a tapered end in order to maintain a steady and compact form of the welding arc. the flattened tip diameter "m," grinding angle "a," and electrode diameter all rely on the strength of the weld current. here is more information on tig electrodes.

what gas is used for orbital welding machine?

specialized gas mixes are necessary for orbital welding in order to get the smooth outcomes you desire. most materials are typically fused using 100% argon gas using orbital welding, while unusual alloys are frequently welded using a mixture of 95% argon gas and 5% hydrogen, depending on the application.

what are the top 5 welding machine types?

there are five primary orbital welding machine types. stick-shielded metal arc welding (smaw), flux-cored - flux-cored arc welding (fcaw), tungsten inert gas (tig), also known as gas tungsten arc welding (gtaw), and plasma arc welding are all types of mig welding (paw). since 1961, orbital welding technique has concentrated on tig welding and has over 25 years of experience in plasma arc welding.

is orbital welding machine automatic?

since the process is fully automated with rotative motors and controllers as well as with a smart welding station (power source), orbital welding is perfect to produce large quantities of welds because of its repeatability and convenient ergonomics. a combination of semi-automatic and mechanised machines may be used in other applications, called automated welding.

which welding machine is strongest?

tig welding produces clean and precise welds if compared to mig welding or other arc welding methods, making tig welding the strongest. that said, different welding jobs may require different methods, while tig is generally stronger and higher in quality, you should use another method if the project calls for it, like manual tacking for example