Orbital orbital welding - introduction, composition

swiss techs chreiner company is pleased to be the official importer and distributor of orbital welding machines in vietnam. we are committed to providing the best products and services to our customers.

introduction to orbital welding machines

orbital welding technologies is a global leader in providing complete solutions for industrial prefabrication, piping installation and maintenance - for everything from pipe cutting and weld preparation to to orbital welding for process and plant engineering.

orbital welding technology offers world-class products that, combined with exceptional service and support, make owt the supplier of choice for tools used for cutting - prep - welding - all from one source.

what is orbital welding machines

orbital orbital welding uses a specialized machine to clamp the pipe or tubes to be welded while the welding arc rotates around the workpiece (in 'orbit'). because the welding parameters are set by the microprocessor, the settings can be stored and reused, making the process highly repeatable.

orbital welding technology or orbital welding is a continuous welding process, the welding seam rotates 360 degrees thanks to the electrode being rotated through the clamp-shaped mechanical structure. the part to be welded is a stationary workpiece such as a pipe. these workpieces are cut with a conventional cutter and then use a tube beveling machine (tube squaring system orbiplan11) to clean the surface or use an orbicut orbital tube cutter.

components of orbital welding machines included?

each orbital welding machines system includes a power control unit, a welding tip, a water-cooled unit, and, where appropriate, a compensating wire feeder. there are a large number of factors that can affect welding results. these include arc length, intensity and pulse repetition frequency of the welding current, welding speed, tip argon and flue gas, compensating rod material, weld preparation, and thermal conductivity. ultimately, a high quality weld can only be achieved through the in-depth knowledge that can precisely adjust all parameters for each individual welding job. getech will train the user, to achieve the best weld quality.

==>see more:

- stainless steel pipe processing

power control (orbital s7 compact mv)

orbital welding machine controller manufactured by owt has advantages over other brands such as:

the controller of the orbital welder is easy to use and precise.

the controller of the orbital welding machine has protection modes for safe and stable operation of the welding machine.

in the process of gmp appraisal, welding data needs to be standardized in every detail. the process of entering welding data takes a lot of time, reducing the welding efficiency of the welder. with new drawings only the name of the weld, do not change the name of the drawing..., the owt welding machine reduces data entry time, increasing working efficiency.

- 7-inch color touch screen integrated in a plastic case with 10 m cable length

- simple operator guidance with symbols (input of pipe outside diameter, pipe wall thickness and welding tool selection)

- gas and coolant monitoring

- divide welding parameters into up to 12 levels

- automatic calculation - continuously or in stepwise mode, according to pipe size and wall thickness

- modify parameters with the current percentage key

- the amperage and wire feed parameters can be changed during welding using the control panel

- round screen of welding process

- instant printing of welding parameters in pdf documents

- any additional information required for a detailed document can be entered directly using the control panel

- unlimited storage of welding programs / unlimited storage of welding programs

- store target and actual parameters in pdf documents on usb

- welding programs are saved with encryption

- software update possible

- 7-inch color touch screen integrated in a plastic case with 10 m cable length

- simple operator guidance with symbols (input of pipe outside diameter, pipe wall thickness and welding tool selection)

- gas and coolant monitoring

- divide welding parameters into up to 12 levels

- automatic calculation - continuously or in stepwise mode, according to pipe size and wall thickness

- modify parameters with the current percentage key

- the amperage and wire feed parameters can be changed during welding using the control panel

- round screen of welding process

- instant printing of welding parameters in pdf documents

- any additional information required for a detailed document can be entered directly using the control panel

- unlimited storage of welding programs / unlimited storage of welding programs

- store target and actual parameters in pdf documents on usb

- welding programs are saved with encryption

- software update possible

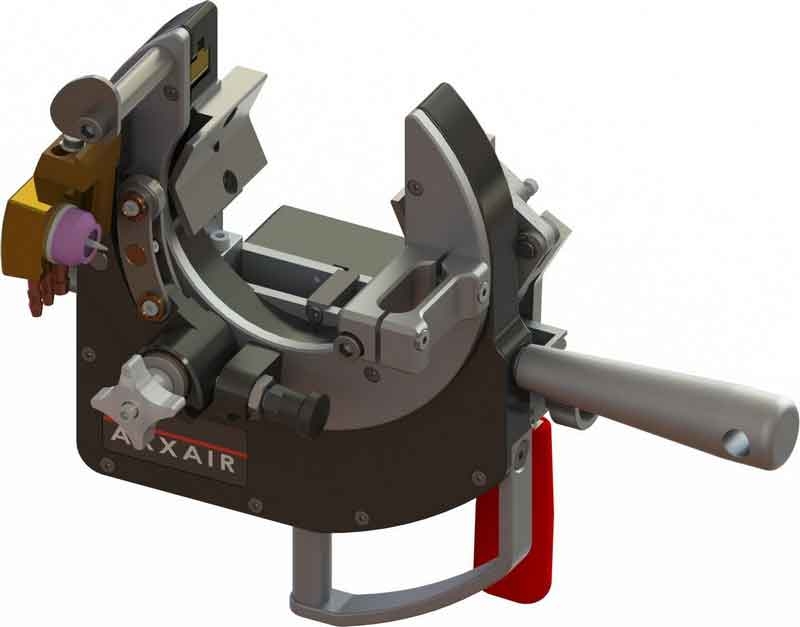

weld heads

the welding head of the orbital welding machine manufactured by owt has advantages over other brands such as:

can weld up to 100 joints/day and night, without worrying about damage. this proved fact.

clamp type clamp, just a simple operation can open the welding head, to change the welding position. other brands of screw clamp will take longer.

the clamp is very tight, can be welded to the pipe, ensuring the quality of the weld during the welding process.

cooling unit with centrifugal pump

water-cooled soldering iron cooler

for compact machines (tkm)

modular design, tool-free assembly

refrigeration capacity 1 l/min: 1000 w, max. flow rate: 5 l/min, max. outlet pressure: 3.5 bar, tank capacity 4.0 l

size lxbxh: 610x300x330mm. weight: 16 kg

110/230v . switchable

expoeeting welding data report

the entire weld history of the day is saved by the welding machine in real time. the picture below is printed with software from the orbital welding machine (owt - germany), the data is saved via usb.

welding data is very important in the gmp appraisal process, the data needs to be accurate, with the data from the orbital welding machine manufactured by owt being exported to a pdf file as an image file, ensuring the verification process is as difficult as gmp. -eu and fda safe (other machines in tex or csv file format)

hopefully with the above basic information, you will better understand the overview of common welding and cutting machines, as well as how to distinguish these types of machines. if you have a need to buy genuine welding and cutting machines, if you have a warranty, please pay attention to buy equipment at reputable suppliers. you can go to the following address to learn and get more advice

ch 4153 reinach and hcm city vietnam

+84931386062 hotline

+84931386062 phone

swiss.tech.schreiner@gmail.com

+84931386062 ( zalo / viber / whatsapp )