Orbital welding technology: Concepts, features

orbital welding technology has been applied in many parts of the world in the fields of medicine, food, biology and high technology. however, in vietnam, these terms are relatively new and little known. so what is this orbital welding technolog?

what is this orbital welding technology?

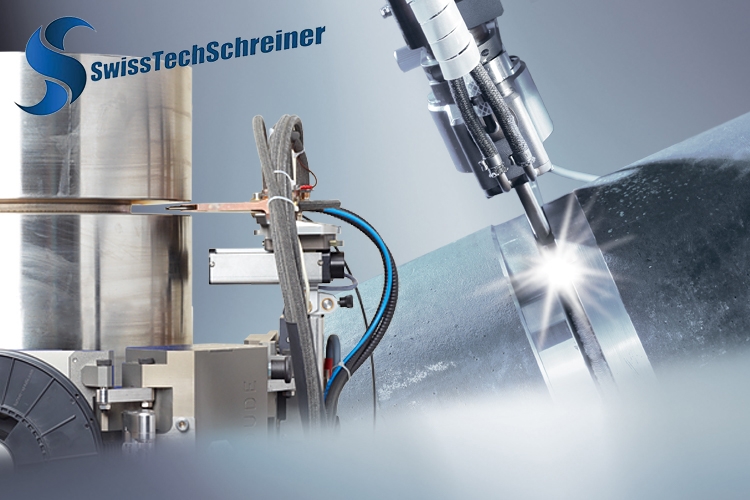

in simple terms, this is a technology of cutting and welding metal pipes in which the equipment will move in a circular orbit around the part to be processed to perform the machining. with orbital cutting technology, the blade will cut slowly into the material, rotating around the cutting part and smoothing the surface of the cut, leaving no three socks. orbital welding technology is based on tig and argon gas welding technology and the welding method revolves around the welding part for bright, beautiful welds and most importantly, high and uniform tightness.

orbital pipe cutting technology is a cold cutting technology, so it does not generate much heat, does not oxidize the material, and does not cause rust. the cut is perfectly chamfered for a flat and clean surface, which is a necessary condition for orbital welding.

orbital welding technology uses tig welding technology and argon gas to prevent material oxidation, welding method with self-circulating welding head around the work piece, along with a closed cooling system to reduce the temperature of the material. material allows welding without altering the properties of the material. due to the orbital cutting process, the gap between the two parts is extremely small, helping the orbital welding process to achieve optimal results in terms of both aesthetics and tightness of the weld.

orbital tube cutting technology was first developed by orbitalum (germany) in the world. orbitalum has become one of the leading companies in the field of cutting tools according to ortbial technology. however, the company did not develop orbital welding technology, but another german company, orbimatic, built and developed orbital welding technology for orbitalum's cutting technology. these two firms have merged to jointly develop orbital technology under the name orbitechnik.

not only that, orbitechnik also merged with p.r.a.i (italy) specializing in tute-to-tube welding technology to develop specializing in pipe processing and welding technology. after many mergers with large companies such as illinois tools work inc (usa) to become stronger, orbitechnik has a new name, goerg fischer (commonly known as gf).

goerg fischer retains the leading position in orbitalum and orbimatic's orbital welding and tube processing technology in today's technology industry.

==>see more:

- stainless steel pipe processing

character of orbital welding technology

features orbital tube cutting technology is that when manipulating, the cutting edge will rotate around the part, cut slowly into the specimen and smooth the surface of the cut, without rust and without burr after manipulation. the cut is beautifully finished, the specimen is not deformed, can create beveled joints for large, thick-walled pipes.

especially because it is a cold cutting technology, it does not generate much heat, which is very suitable for cutting operations in the field that require operations that prevent sparking such as maintenance and repair for the home pipeline system. beer, wine, food, microbiology (pipelines require high purity). is the preparation for the welding of orbital pipes.

ch 4153 reinach and hcm city vietnam

+84931386062 hotline

+84931386062 phone

swiss.tech.schreiner@gmail.com

+84931386062 ( zalo / viber / whatsapp )