Reasons to use Orbital welding machine

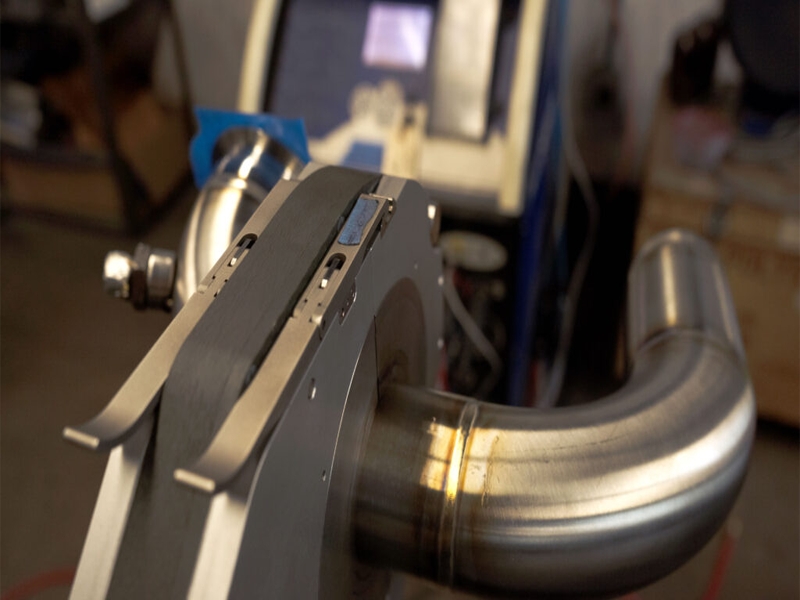

there are many reasons to use an orbital stainless steel pipe welder. it is the ability to deliver high quality results, repeatable uniform welds at speeds close to full welding speed for the benefit of the user. let's find out the reason the business should use orbital welding machine with swisstech schreiner.

the reason business should use orbital welding machine

orbital welding machine play a big part in tube and pipe welding in industries such as orbital pharmaceutical, aerospace, brewery, food / dairy / beverage industry. heat exchanger manufacturing, nuclear, petrochemical, semiconductor, wastewater treatment.

1. productivity: the orbital welding machine system will perform faster and more powerfully than manual welding, the cost is also many times more economical for stainless steel pipe welding.

2. quality: the quality of the welds produced by the orbital pipe welding system adjusted by the automatic welding program will yield higher quality results than manual welding. in applications such as semiconductors and pharmaceuticals, orbital tube welding is the only method that provides the most satisfactory welds.

3. uniformity: as soon as the welding program is established, the orbital welding system will repeat the welding performance of hundreds of identical welds. eliminate common errors such as variations, inconsistencies, errors and defects of manual soldering.

4. skilled worker: it is difficult to get a highly certified welder. with orbital welding equipment you will not need a special skilled welder. all you need is a welder who has learned the basics and attended some swisstech company training.

orbital welding is used in applications where the tube (tube or pipe) to be welded cannot be rotated or the position to rotate the part is not feasible.

orbital welding is also used in situations where the access space is limited, which limits the size of the hand-feeding equipment. orbital welding heads can be used to weld tube beams in boilers where it is difficult to hand weld with a torch and the weld is difficult to see.

there are many other reasons for the existence of automatic pipe welding equipment compared to manual welding. for example, applications where quality inspection of the inside of a weld is not possible for each weld created. at that time you will choose an automatic pipe welding machine with orbital technology. by examining a group of welds sampled, if achieved, it is considered acceptable. since successive welds are generated by the automatic welding equipment with the same parameter inputs, the same quality results will be obtained.

orbital welding machine supplier - swisstech schreiner

orbital welding technology has been applied in many parts of the world, especially in the fields of medicine, food, biology and high technology. however, in vietnam, this is a fairly new technology and only a few foreign-invested houses apply.

in vietnam, orbital welding machine are supplied by a number of brands from the eu, g7 and china such as: tag-pipe, gf, mausitalia, axxair, orbitalum, lefon. the price depends on the quality and origin of the machine, the price ranges from a few tens of millions of dong (for chinese goods) to several hundred million dong (for tag-pipe, orbitalum, mausitalia goods..).

depending on the investment capital, businesses can choose the appropriate type of welding machine. however, in terms of total productivity, we recommend that you buy axxair to get the best work efficiency, machine depreciation time is 3 times longer than other machines. more importantly, axxair's service is very good, there are representatives in vietnam - swisstech, so you can get technical support when the device has problems.

whatever the scale of your operation, you’re sure to find the ideal piece of equipment in our vast selection of orbital welding equipment at swisstech schreiner. we provide machines with all at affordable prices with warranties but if limited by budget you should consider the rental of one of our systems.

swiss tech schreiner.

add: ch 4153 reinach and hcm city vietnam

hotline: (+84) 931 - 386 - 062

phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

email: swiss.tech.schreiner@gmail.com