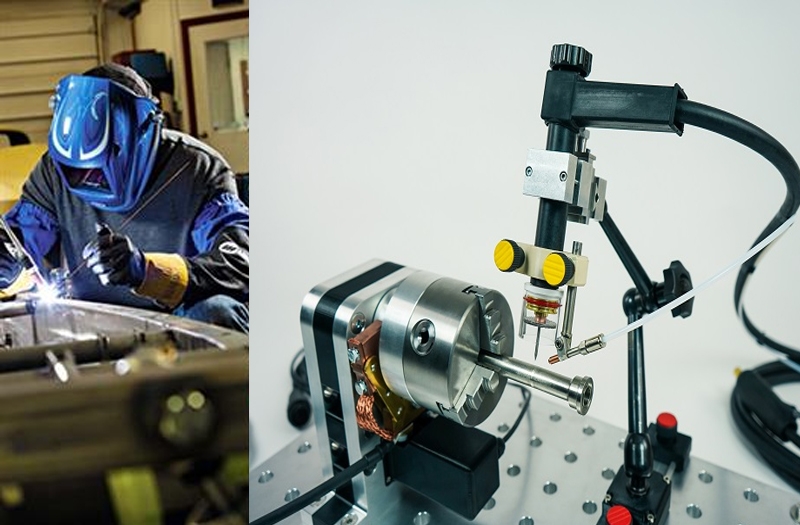

Welding Machine Maintenance Work Instruction

maintaining your welding equipment properly is one of the most crucial - and simplest - ways to produce robust welds. in terms of machine life as well as welding performance and quality, maintaining your welder machine is easy to do and can end up saving you a lot of time and money. proper machine maintenance work will help you avoid some common welding failures and help you avoid paying for costly repairs on improperly maintained or neglected equipment.

depending on the type of welding equipment you are using, maintenance requirements will vary. the following article we will go to share about the welding machine maintenance work welding for your reference.

properly maintenance work welding

electric welding machine is a modern device and is used quite commonly in the human labor process. however, in the long-term labor process, many components of the welding machine will be prone to malfunctions, errors in some machine parts and very difficult to repair. therefore, we need to understand how to best maintain electric welding machines to help improve the life and performance of electric welding machines, and at the same time avoid unintended accidents due to technical problems from machine failure during work.

here are some important steps in maintaining the best electric welder:

- first, we have to check all the parts of the machine before working, to see if every part of the machine is still in good working order or not. make sure the equipment is grounded and not too dusty. if any part of the machine is found to have signs of failure, it must be corrected in time to avoid causing damage to other parts of the device. machine.

- next, we must understand how the machine works before starting the machine. know how the installation works and check back often according to the manufacturer's instructions. with electric arc welding machines, the ground should be placed and care should be taken to avoid fire and explosion. also, use accessories suitable for the machine type.

- ensure a safe, clean and well-ventilated workplace. strictly control the equipment situation against external influences.

- when in use, it is necessary to set the correct working hours, electrodes and fillers in the welding process must conform to the manufacturer's instructions. if the setting is wrong or not paying attention to the manufacturer's instructions, it will lead to the machine's condition, even causing an explosion.

- store the device in a dry and safe place after use. equipment can be damaged if dropped or bumped, and corroded if exposed to high humidity environments, dust accumulation in electrical circuits or important parts can cause the machine to fail quickly or reduce performance. job.

at the same time, we should also choose quality electric welding machines from reputable stores in the domestic market, to avoid buying the wrong product with low quality, high price,... if we apply the best maintenance methods for electric welding machines, we will certainly prolong the life of our equipment and increase labor productivity in the process of working.

performing the above maintenance work welding stages on a regular basis will definitely help the welding machine always achieve high efficiency in operation and have a long life. do not forget to refer to the good quality welding machines at swisstech to distributing genuine products at affordable prices.

swiss tech schreiner.

add: ch 4153 reinach and hcm city vietnam

hotline: (+84) 931 - 386 - 062

phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

email: swiss.tech.schreiner@gmail.com