Why Should You Apply Orbital Welding Technology?

is orbital welding really the right process for your unique application? orbital welding was first used in 1960, when the aerospace industry recognized the importance of joining techniques for hydraulic lines.today, orbital welding technology is not only for aerospace but also applied to industries such as food and chemical processing, bio-pharmaceutical processing, electronic and semiconductor manufacturing.

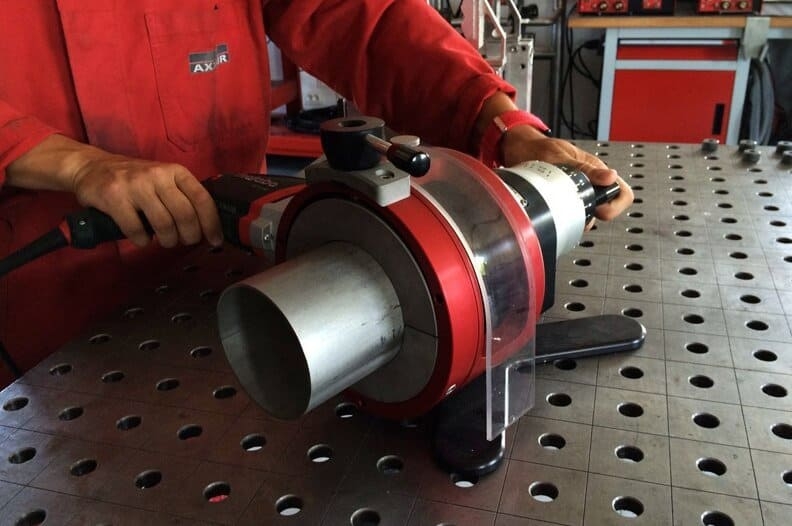

what is orbital welding?

orbital welding technology or orbital welding is a continuous welding process, the welding seam rotates 360 degrees thanks to the electrode being rotated through the clamp-shaped mechanical structure. the part to be welded is a static workpiece such as a pipe.

orbital tig welding allows an operator to maintain precise control of amperage and heat input, travels speed and filler metal use, in order to achieve consistent, reliable welds of high strength, continuity and cleanliness, with minimal deformation or contamination.

now that we’ve taken a step back to learn more about orbital welding, its history and applications, let’s continue to discuss some additional benefits of this semiautomatic welding process.

6 reasons you should choose orbital welding technology

1. higher weld quality

this can be crucial in applications within certain industries like the semiconductor and pharmaceutical industries, where there are strict requirements to be met.

2. higher productivity

orbital welding is a much more productive use of labor, as the machinery is doing the majority of the work and does the work faster than manual methods.

3. error reduction

welders can set the welding equipment to a specific program, allowing the system to repeat the exact same welds over and over again, minimizing error or defects.

4. practicality

orbital welding equipment allows welding in all situations, including confined spaces, lack of visibility and high-risk environments. welding can be performed from a remote location and a special welding camera can be added to the equipment, reducing risk for the operators.

5. ease of use

in contrast, operating orbital welding equipment is possible without a long and tedious training program and does not require you come from an accomplished welding background.

6. cost reduction

because orbital welding uses automated processes, it is much more efficient and cost-effective than manual welding practices. the mechanization of the orbital welding process helps to reduce the time needed to actually perform the welds. with less production time needed for the welds, your shop can experience significant cost savings. additionally, since orbital welding reduces the chance for error or defects, less time and money is spent on repairs.

swiss tech schreiner.

like many great businesses, swiss tech s. began in a garage. the year was 1990, and lothar schreiner had decided to take his decade of experience in the food processing industry and strike out on his own. with a commitment to hard work, honesty and customer service, swiss tech s. has steadily grown and is currently the largest employer of sanitary welders in west germany. in order to offer its customers in the food, beverage, and pharmaceutical industries a complete range of coverage the company supports a large staff including mobile crews, project managers, engineers, and administrative support.

add: ch 4153 reinach and hcm city vietnam

hotline: (+84) 931 - 386 - 062

phone: (+84) 931 - 386 - 062

+84931386062 ( zalo / viber / whatsapp )

email: swiss.tech.schreiner@gmail.com